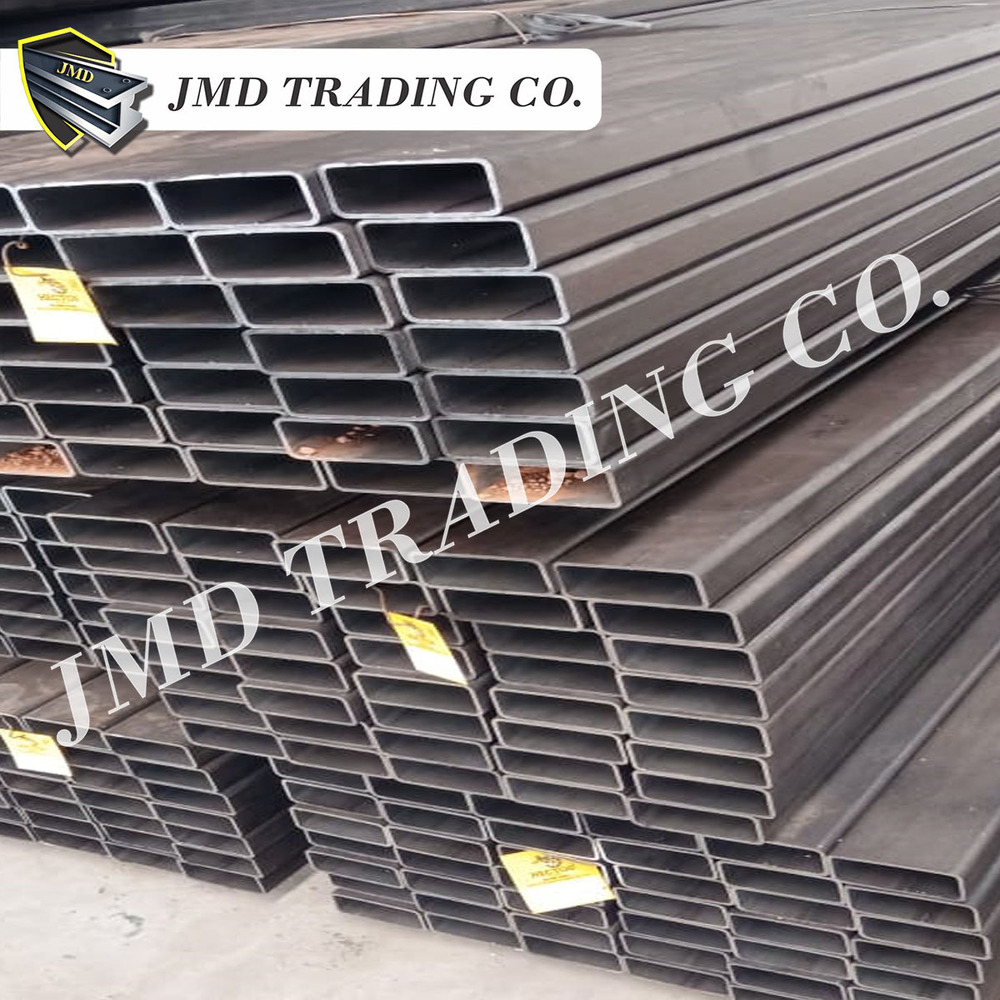

MS Square Pipe

Price 48011 INR/ Ton

MS Square Pipe Specification

- Alloy

- Non-Alloy

- Product Type

- Other

- Connection

- Welded, Sockets

- Application

- Structural, Fabrication, Construction, Industrial

- Surface Finish

- Galvanized, Painted, Mill Finish

- Material

- Mild Steel

- Steel Grade

- IS 2062

- Type

- ERW

- Shape

- Square

- Standard

- IS 4923 / ASTM A500 / BS EN 10219

- Grade

- IS 2062 / E250 / E350

- Surface Treatment

- Hot dip galvanized / painted / oiled

- Technique

- Electric Resistance Welded (ERW)

- Thickness

- 1-12 Millimeter (mm)

- Outer Diameter

- 20 mm - 200 mm

- Length

- 6 m standard / custom length available

- Tolerance

- 0.5 mm

- Color

- Grey / Black

- Delivery Condition

- As per customer requirement

- Custom Size Availability

- Yes

- Manufacturing Process

- Cold Rolled / Hot Rolled

- Usage Temperature

- -20°C to 90°C

- Yield Strength

- 250 MPa

- Corrosion Resistance

- Yes (if galvanized or painted)

- Tensile Strength

- 410 MPa

- MOQ

- 1 ton

- Pipe Ends

- Plain / threaded ends on request

- Density

- 7.85 g/cm³

- Weight per meter

- As per size (eg. 2.2 kg/m for 25x25x2 mm)

- Pack Type

- Bundle / loose

MS Square Pipe Trade Information

- Minimum Order Quantity

- 5 Tons

- Supply Ability

- 500 Tons Per Day

- Delivery Time

- 1 Days

- Main Domestic Market

- All India

About MS Square Pipe

We have been marked in dealing a broad array of MS Square Pipe. It is extremely resistant to temperature and pressure. This pipe is used to reduce the cost of less budget items. It is resistant to fire and break resistant in nature. MS Square Pipe is made with a high tensile strength to tolerate the high strength. Provided pipe is suitable for building, heavy structures and other industrial applications. It is also aid for supply of drinking water.

Specification

|

Thickness |

1.00 MM TO 12.00 MM |

|

Nominal Bore |

19X19X1.00 MM TO 300X300X12 |

|

Brand |

ALL LEADING BRANDS |

|

Material |

MS |

|

Weight |

4 KG TO 650 KG |

|

Shape |

SQUARE |

|

Color |

Black |

Superior Structural Performance

With a yield strength of 250 MPa and tensile strength of 410 MPa, MS Square Pipes offer reliable structural integrity. The product adheres to IS 2062 and IS 4923 standards, making it suitable for heavy-duty construction and industrial use. Custom sizes and finishes are available to meet specific project requirements.

Versatile Application Range

Designed for flexibility, MS Square Pipes can be used in construction, fabrication, and various industrial frameworks. Their non-alloy, mild steel composition ensures compatibility and durability, while options for threaded or plain ends and multiple surface treatments enhance usability in diverse settings.

Customizable and Corrosion Resistant

Clients can choose pipe lengths, diameters, finishes, and manufacturing processes to fit project needs. When galvanized or painted, the pipes deliver excellent corrosion resistance, extending service life even in challenging environments. Orders are supplied as bundles or loose pieces, accommodating different logistical preferences.

FAQs of MS Square Pipe:

Q: How is the corrosion resistance of MS Square Pipes ensured?

A: Corrosion resistance is achieved through surface treatments such as hot dip galvanizing, painting, or oiling. When galvanized or painted, MS Square Pipes can withstand challenging environments, minimizing the risk of rust and deterioration.Q: What process is used to manufacture these pipes?

A: MS Square Pipes are produced using Electric Resistance Welded (ERW) technique, with cold rolled or hot rolled processes depending on specific grade and application requirements. This ensures uniform thickness and a strong welded seam.Q: Can I order MS Square Pipes in custom sizes and lengths?

A: Yes, custom sizes and lengths are available on request. While the standard length is 6 m, suppliers accommodate special dimensions and wall thicknesses according to project specifications.Q: Where are MS Square Pipes commonly used?

A: They are widely utilized in structural frameworks, fabrication, construction, and industrial applications. Their robust design supports structures, machinery frames, and fabrication projects demanding consistent strength and stability.Q: What are the benefits of choosing MS Square Pipes with IS 2062 grade?

A: IS 2062 grade mild steel offers a balanced combination of mechanical strength, weldability, and durability. Pipes manufactured to this standard are suitable for a wide range of structural and engineering applications in India.Q: How should the pipes be connected in various applications?

A: MS Square Pipes can be connected through welding, using sockets, or by threaded ends if requested. The plain end is standard, but the supplier can provide threaded ends for specific joining methods.Q: When is it advisable to choose galvanized or painted MS Square Pipes?

A: Galvanized or painted pipes should be selected when corrosion resistance or extended service life is required, particularly in outdoor or moisture-prone environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in MS Pipe Category

MS Round Pipe

Price 45211 INR / Ton

Minimum Order Quantity : 5 Tons

Material : Mild Steel

Shape : Round

Technique : Other, ERW (Electric Resistance Welded) / Hot Rolled

Thickness : 3.6 Millimeter (mm)

MS Rectangular Pipe

Price 45211 INR / Ton

Minimum Order Quantity : 5 Tons

Material : Mild Steel

Shape : Rectangular

Technique : Other, Hot Rolled, Cold Rolled, ERW (Electric Resistance Welded)

Thickness : 112 Millimeter (mm)

MS Pipe

Price 45011.00 INR / Ton

Minimum Order Quantity : 5 Tons

Material : Mild Steel

Shape : Square

Technique : Hot Rolled

Thickness : 111 Millimeter (mm)

|

JMD TRADING CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry